The Application of Data-Driven Methods and Physics-Based Learning for Improving Battery Safety

This post is an industrial outlook on the review article “The Application of Data-Driven Methods and Physics-Based Learning for Improving Battery Safety” by Finegan, Zhu, Feng, Keyser, Ulmefors, Li, Bazant, and Cooper (2021).

Li-ion cells are non-linear and non-deterministic systems

The behavior of Li-ion batteries throughout their lifetime is nonlinear, with a plethora of dynamic electrochemical and mechanical phenomena occurring within the cell at any point in time, whether operating or not.

Two cells of identical geometry, chemistry, and history might respond differently when exposed to identical mechanical, thermal, or electrical stimuli.

The authors also state that Li-ion cells are complex systems. I don't agree with this. While Li-ion cells have some properties in common with complex systems, such as hysteresis and non-linearity, cells don't behave in emergent ways which we cannot predict by analysing the cell's components. Or, at least, so we hope :)

Induce short circuit in test cells to get more data for model training

The authors suggest that it's hard to train a physics-agnostic model to predict cell failures from the data because there are too few cell failures and the data to train from. I agree with this.

To get more data for model training, the authors suggest to artificially induce short circuits. I think this is a practical idea.

The authors enumerate several ways of inducing short circuits in cells, or increasing their probability:

Replace a part of separator with wax with low melting point;

Strain the separator by dropping, bending, or pressing the cell;

Insert a small conducting object into the cell and then press the cell to puncture the separator;

Cycle the cell at high temperature.

I would also add to this list:

Cycling cells at freezing cold temperatures can lead to rapid Lithium plating and induce failures, too.

Apply very high charge or discharge current to the cells.

I think mechanically stressing the cell and cycling at extreme temperatures and high currents are the most practical approaches because cells from the main manufacturing line can be used. Also, both are real-life scenarios for how the cells can actually fail.

The downside of these approaches is that cells can still fail only rarely even after such abuses, so to avoid wasting a lot of cells, short circuit induction should be integral part of the general cell modelling and cell parameter verification process.

On a similar idea, we can take the cells that performed poorly during the end-of-line testing and cycle them to death, hoping that these cells are more likely to fail in the process than normal cells.

Intentionally inserting a small conducting object between cell's foils also captures a possible real-life scenario, but the cells should be created bespoke in the lab.

To counter their own ideas, authors write:

However, it can be difficult to confidently relate [results obtained for cells on which failures were artificially induced] back to predictions about normal cells under standard operating conditions.

I can see that the statistics of failures of cells cycled at high temperature might not apply to cells cycled at different temperatures.

However, I think that separator failures should be characterised by a phase transition of one or several cell parameters (such as Cell self-discharge rate and Cell internal resistance). The transition patterns might be different for different types of separator failures (e. g. Lithium dendrite vs. spurring vs. tearing), but I don't think the transition patterns depend on how the separator failures where brought about. Therefore, the models for early detection of cell failures should work well for cells in real operation even though these models are trained on the data from the controlled experiments.

On recording and using physical data beyond voltage and current

The authors point out that until now, data-driven prediction models have mostly used only the voltage and the current data from the cells.

Alternative simultaneous operando measurements are needed to help gain physical insight into the system and to interpret the causes of behavioral divergence.

The authors suggest more physical measurements:

Electrochemical impedance spectroscopy

Force sensors or thin-film strain gauges to detect cell's swelling, expansion, or contraction

Acoustic analysis of cells

Monitoring acoustic emissions from particle cracking

Measuring external and internal temperatures of cells, with thermistors and thermal imaging

I think this is not economically viable to measure anything of these on a significant portion of cells in real battery packs. Therefore, we cannot use this additional data to predict cell failures in the field.

Actually, in real batteries of cylindrical cells, even voltage and current are not measured for every individual cell, but only for whole groups of cells connected in parallel. This significantly dilutes the signal coming from each separate cell and makes it much harder to detect parameter phrase transitions happening in a single cell in the group. Because of this, it might not be possible even to apply the existing algorithms of cell characterisation, monitoring, and prediction which use the voltage and the current as inputs.

So, I think that we don't have cell failure prediction in real packs mainly because we cannot afford to add even minimal sensing to every cell within a pack in isolation, and not because we cannot create algorithms or models. This reminds me of Stuart Russell saying that decent algorithms for autonomous driving existed in mid-nineties, but the main problem was perception.

Collect data for a purpose

The extra physical data can be obtained in the lab and used to better understand the physics of the cells and the mechanisms of failures. However, it's not obvious how this better understanding will translate into practical advances in the battery technology. For the practical purposes of cell or battery pack engineering, I think it's really important to first state the exact questions we wish to answer, or the exact ways in which better understanding of so-and-so cell failure scenario or a degradation mode can help us to make more reliable batteries. (Personally, I can't come up with anything.) Then, we should deliberately think what data we need to collect to answer these questions. Without doing this first step, it's very likely that just collecting more physical data won't lead us to any important insight, and even if it will, the gained insight likely won't help us to improve the battery designs.

In relation to this, I want to recount another Stuart Russell's opinion:

Data is not the new oil, it is “snake oil”. Amassing a pile of data without thinking about the problem you wan to solve or the higher level goal is just a waste of money, there's no value in it.

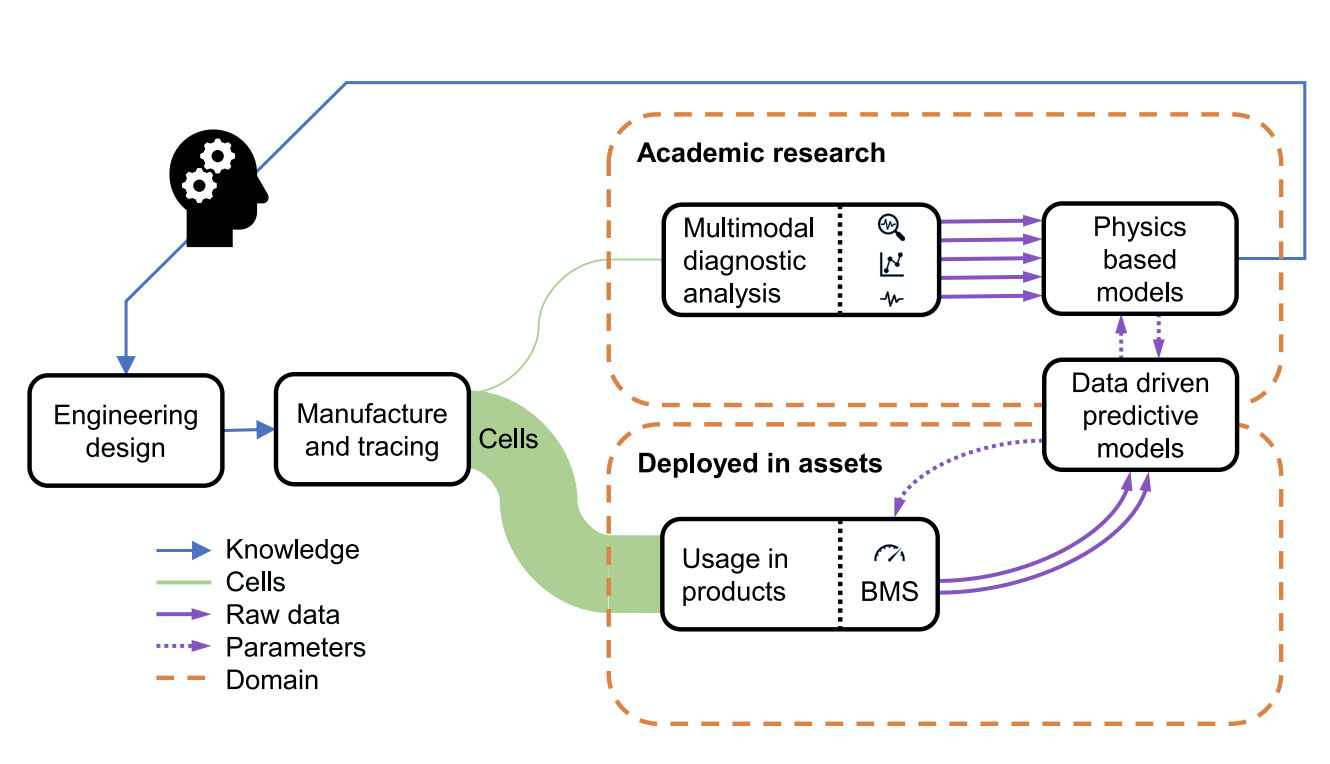

Why physics-based models?

The authors write:

[A physics-agnostic model] presents limited value in informing researchers and engineers on design opportunities to improve the cells’ performance.

Physics-based or physics-inspired models (i. e., equivalent-circuit models) can make researches aware of the gaps in their understanding of the cell physics specifically when these models will fail to capture the cell's voltage response to the electrical current input. Therefore, it's important not to add arbitrary "learned components" to the physics-based model, or to build physics-guided neural networks. Such models can easily compensate for some wrong assumptions about the cell's physics, which would essentially be overfitting.

But in real operation, the battery management system should include as accurate model of a cell as possible, regardless of how "physical" it is. So this could be a neural network, i. e. a different model than the one used by the cell designers.

[Machine-learning models] are fundamentally interpolative and cannot be expected to predict behaviors outside of the training data envelope; alternatively, a well-parameterized physics-based model should be able to extrapolate if the correct physics has been selected.

I'm more defensive here: in my opinion, Li-ion cells are predictable enough for interpolative algorithms to cover most of the ways in which cells can fail. It's highly unpredictable whether any given cell will fail and when, but overall, failures should fall into a limited number of recognisable scenarios.

It seems to me that the most practical approach is to leverage our understanding of the cell's electrochemistry "lightly" by estimating the features of a cell from the cell telemetry, instead of hoping a deep neural network to figure out all these parameters by itself:

Cell self-discharge rate

Cell open-circuit voltage function (e. g. from state-of-charge). For example, it was used as a feature for a model predicting cell cycle life in [1].

Or, simpler features: the open-circuit voltage at 0%, 100% SoC.

But then, after estimating all these cell parameters (see more on how to this below), I think we can use more generic statistical algorithms and pattern recognition to estimate the cell's state-of-health and the risk of failure.

However, I'm not sure we have enough information in battery packs of small cylindrical cells even to estimate the parameters of the cells. The authors write:

[Electric Vehicles] contain sufficient on-board instrumentation, telemetry, and computing power to share detailed pack diagnostics and prognostics.

I think this can only be true for batteries of large prismatic cells, where we can monitor the voltage and the current on every cell separately. For cells of cylindrical cells, this is not economic.

The authors also write that physics-based models help to identify critical operation conditions:

Identifying the most critical condition [under which a mechanical failure or short circuit is most likely to happen] is of great real-world value for the automotive industry to reduce the size of the test matrix, standardize the test condition, and guide the passive safety design of electric vehicles.

I think we already a good idea on what these critical conditions are: extreme temperatures (high and low) and high currents. But I agree this is useful that BMS can compute more precise power limits with a good physics-based model.

Convert an electrical cell model into a stochastic parameter predictor

The authors suggest to apply the approach from [2]: to probabilistically predict cell's parameters by training a variational autoencoder (VAE) model after pre-training using the output of an electrochemical cell model. Pre-training on the electrochemical model output (i. e., a simulation output) essentially regularises the VAE model.

Having a stochastic framework for estimating all parameters at once is essential because the Li-ion cell has just a single output signal: voltage. The changes to the voltage response can often be attributed to changes in different cell parameters (e. g., self-discharge rate, or the open-circuit voltage relationship, or charge capacity). Estimating all parameters in separation (e. g. using linear regression) will overreact to the changes in the cell by fully attributing them to several different parameters. Moreover, the variances of the estimates of the different parameters will not be coherent.

Even a Kalman Filter estimating all cell's parameter at once will likely fail to discern the contributions of different cell's parameters to saddle changes in the voltage response of the cell. This is because the classic Kalman Filter keeps only the latest estimated parameters as its state and doesn't consider the telemetry history holistically. For example, the changes in the Coulombic efficiency and in the self-discharge rate lead to approximately the same effect unless we predict the parameters considering at least several charge/discharge cycles of different lengths.

References

[1] "Data-driven prediction of battery cycle life before capacity degradation" (2019)

[2] "Variational Auto-Regularized Alignment for Sim-to-Real Control" (2020)